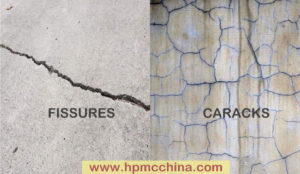

Analysis of the causes with Cement-based mortar,Exterior wall putty fissures and cracks.

Cement-based mortar,Exterior wall putty fissures and cracks,These are all common problems.In many years of research and practice, reasons for the formation of Cement-based mortar,Exterior wall putty fissures and cracks.I think it can be divided into two aspects: "MATERIAL ESSENCE" and "OUTSIDE ENVIRONMENT"

1.“MATERIAL ESSENCE ”

1.“MATERIAL ESSENCE ”

"Material essence" can also be called the property of the material itself.Due to the large shrinkage and quick shrinkage of some plastering mortars and putty products, large internal stresses cause damage to the mortar structure and cause cracks. The cracks generally exhibit irregular cracks, which is also known as cracking.Mainly some manufacturers do not fully understand the nature, function and technical principle of raw materials. The raw materials used do not meet the requirements, and the formula is unscientific, resulting in unstable product quality and poor crack resistance.shortly after construction, there was a large area of cracking, hollowing, and falling off.

The strength and anti-cracking effect of cement mortar are all related to water.The hydration and condensation hardening of cement is a gradual, continuous process, first hydration, then condensation,the result of condensation hardening depends on the hydration conditions, the more adequate the hydration, the better the water conservation, the longer the curing time, the higher the strength, the smaller the shrinkage, and the better the crack prevention effect;The hydration and condensation hardening rate of cement is also affected by the ambient temperature, that is, the ambient temperature is high, the hydration and hardening speed is fast, and when the ambient temperature is low, the speed of cement hydration and condensation hardening is correspondingly slower.Any cement mortar that is dry early, early hard, and strong early, due to poor water retention and poor self-supporting ability, will produce excessive shrinkage, excessive shrinkage, and easy to produce large-area cracks.In research and practice, the late strength, stability and crack resistance of cement mortar with early drying, early hardening and early strength are worse than cement mortars with late dry, late hard and late strength. This is also the cementity of cement as inorganic. The specificity of the cementitious material is determined.

The cracking of the turtle is mainly related to cement. No matter what type of cement, there is a problem of shrinkage.From the test situation, the late strength, stability and crack resistance of cement grades such as sulphoaluminate cement and white cement are not as good as ordinary Portland cement, mainly because these products have large shrinkage and quick shrinkage. Strong contraction force, easy to produce turtle cracks.

Ordinary Portland cement is widely used in China's construction projects. It has a history of several decades, and its performance is very good. After research and experiment, as long as the hydration is sufficient and the water conservation conditions are good, after a few years Even after ten years, its strength will increase.At present, polymer mortar and cement putty are still dominated by ordinary Portland cement. The model used is 32.5R or 42.5R, and the formulation amount in polymer plastering mortar and cement putty products must be mastered.

2.“OUTSIDE ENVIRONMENT “

2.“OUTSIDE ENVIRONMENT “

The “outer environment” is mainly caused by construction technology, foundation and natural environment. Under normal circumstances, the design and construction of the building is unscientific and unreasonable. The foundation is settling and deviating. The construction is too thick at one time. The foundation before construction has obvious cracks, earthquakes, stress caused by large wind pressure, and continuity after construction. High temperature and dry weather, etc., will cause cracks. The cracks and cracks generally have cracks, and the shapes are horizontal, vertical or irregular.

Another characteristic of cement-based mortar,exterior wall putty fissures and cracks is that no matter how thick or thin, the fissures and cracks are cracked from the surface to the bottom, which is the most fundamental cause of leakage in buildings. the fissures and cracks vary in size.Large fissures and cracks can be easily seen. Small fissures and cracks are not necessarily visible to the naked eye, but as long as water is poured onto the dry wall, fine fissures and cracks can be clearly seen.

As long as fissures and cracks appear, basically no reliable materials and technical means can be completely repaired, and the results will cause great difficulties for building decoration, decoration, waterproofing and future maintenance work.

This is because the fissures and cracks in the external wall change with the external environmental conditions (foundation settlement, earthquake, etc.) and large temperature difference and dry humidity, and the gap size and shape also change continuously. The gap size will change during low temperature in winter and high temperature in summer, that is, in the same season, rainy days and clear days, the gap size will also change.In short, 24 hours a day is changing, which is also the crack in the roof, wall, underground waterproof engineering and maintenance practices, but also the most headache, often after repair, less than a year or even months Inside, it began to leak again.As long as there are no fissures and cracks, under normal circumstances, there will be no leakage of water in the building. Anyone who knows the cement pool will understand that as long as there are no cracks, the cement pool will not leak.